TECHNO CHEMICAL corp.

生化学・免疫学等の研究用試薬及び関連機器輸入販売

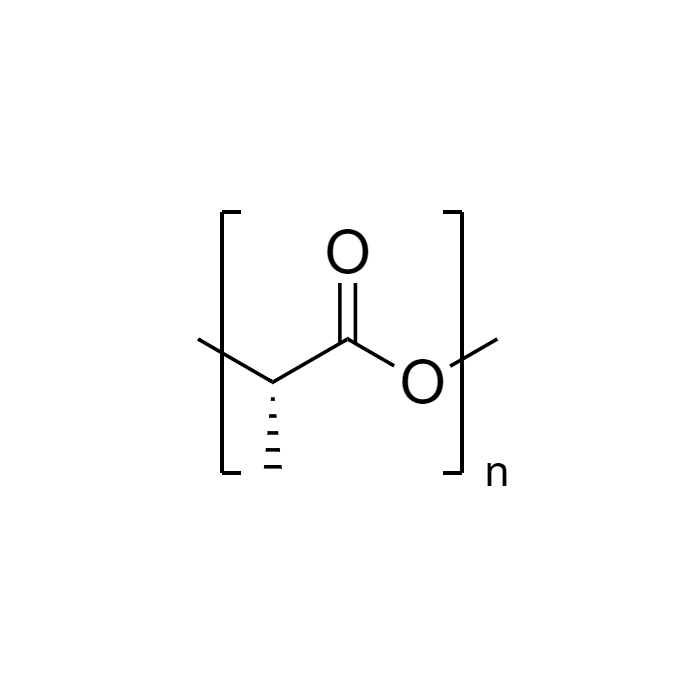

| Poly(L-lactide), IV 1.6 dL/g | ||

ポリ(L-乳酸) (PLLA) は、生体吸収性および生分解性のポリマーで、その優れた生体適合性と機械的特性により、バイオメディカル業界で非常に求められています。縫合糸、骨プレート、組織スキャフォールド、ドラッグ デリバリー システムなどの医療機器の製造に広く使用されています。また、PLA は細胞の成長をサポートし、組織の再生を促進する能力があるため、組織工学用途での使用も増加しています。 PLA は、その生分解メカニズムが十分に研究されており、主な生分解経路はエステル結合の加水分解によるものであるため、バイオメディカル業界で頻繁に活用されています。生分解速度は、特定の用途、分子量、最終材料の厚さ、pH、酵素への曝露の程度、その他の生物学的要因などの要因に基づいて変化する可能性があります。 ポリサイエンス社は、お客様の研究ニーズに適した、さまざまな分子量の PLA ホモポリマーおよびコポリマー製品をいくつか提供しています。 別名:PLA、PLLA、ポリ(L-乳酸)、L-ラクチドポリマー、ポリ乳酸 粘度:~1.6 dL/g [i.v.] 外観:白色〜オフホワイト〜淡黄褐色個体 論文:

| ||

| Cat.# | 容量 | 定価 |

|---|---|---|

| 50045-5 | 5 g | ¥53,800 |

| 50045-25 | 25 g | ¥243,000 |

| CAS | 26161-42-2 |

| 保管温度&取扱: | -20℃/禁湿気 |

| 出荷温度: | ドライアイス出荷 |

〒113-0021 東京都文京区本駒込1-27-9 TEL 03-3947-7310 FAX 03-3947-7306 |