|

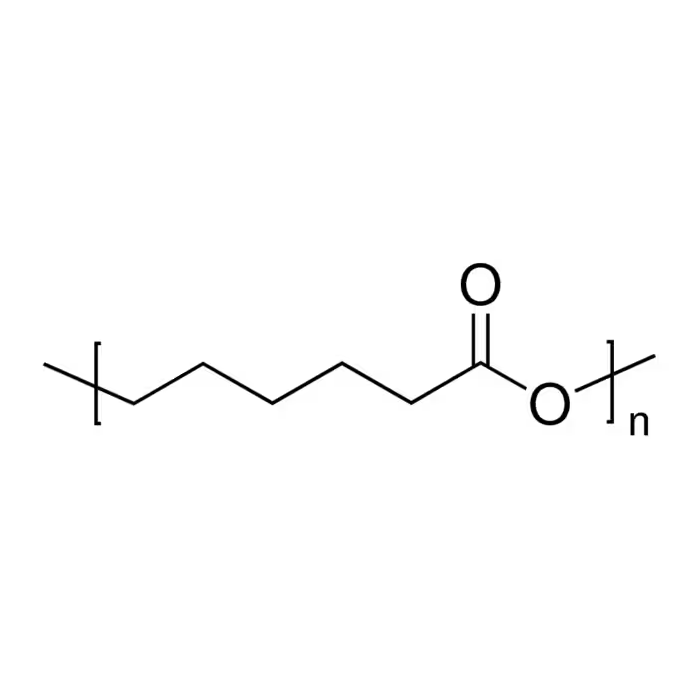

ポリカプロラクトン (PCL) は、半結晶性で疎水性の生分解性ポリエステルであり、生体適合性、化学的および物理的に扱いやすいこと、分解速度を調整できることから、バイオメディカル ポリマーとして人気を博しています。フィルム、繊維、3D プリント スキャフォールドなど、さまざまな形状に加工できる多用途のポリマーであるため、組織工学や薬物送達の幅広い用途に適しています。 PCL は、生理的条件下でエステル結合の加水分解によって分解されますが、ポリグリコリド (PGA)、ポリ乳酸 (PLA)、およびそれらの共重合体などの他の一般的な生分解性ポリマーよりも遅い速度であるため、長期インプラントに使用できます。一般に、分子量が大きい PCL は分解速度が遅くなります。温度、pH、酵素の存在、表面積と体積の比率、および特定の用途も、PCL の分解速度に影響します。 PCL の融点が低い (約 60℃) ため、柔軟性が高く、3D 印刷、フィルム形成、熱成形に便利です。 PCL は生分解性があるため、さまざまな用途で多くの生態学的に持続性のあるプラスチックの環境に優しい代替品にもなります。 別名:PCL、カプロラクトン ホモポリマー、(1,7)-ポリオキセパン-2-オン、ポリ (ヘキサノ-6-ラクトン)、2-オキセパノン ホモポリマー、6-カプロラクトン ポリマー Tg:~ -60℃ 粘度:~0.4 dL/g [i.v.] 外観:白色〜オフホワイト個体 生分解時間:約1〜2年 論文: - Cho YS, Gwak S-J, Cho Y-S. Fabrication of Polycaprolactone/Nano Hydroxyapatite (PCL/nHA) 3D Scaffold with Enhanced In Vitro Cell Response via Design for Additive Manufacturing (DfAM). Polymers. 2021; 13(9):1394. https://doi.org/10.3390/polym13091394

- Seyedsalehi, A., Daneshmandi, L., Barajaa, M. et al. Fabrication and characterization of mechanically competent 3D printed polycaprolactone-reduced graphene oxide scaffolds. Sci Rep 10, 22210 (2020). https://doi.org/10.1038/s41598-020-78977-w

- Yong Sang Cho, Meiling Quan, Nae-Un Kang, Hun-Jin Jeong, Myoung Wha Hong, Young Yul Kim, Young-Sam Cho, Strategy for enhancing mechanical properties and bone regeneration of 3D polycaprolactone kagome scaffold: Nano hydroxyapatite composite and its exposure, European Polymer Journal, Volume 134,2020, 109814, ISSN 0014-3057, https://doi.org/10.1016/j.eurpolymj.2020.109814.

- Cho, Y. S., Quan, M., Lee, S.-H., Hong, M. W., Kim, Y. Y., & Cho, Y.-S. (2019). Assessment of osteogenesis for 3D-printed polycaprolactone/hydroxyapatite composite scaffold with enhanced exposure of hydroxyapatite using rat calvarial defect model. Composites Science and Technology, 107844. doi:10.1016/j.compscitech.2019.107844

- Ho, C.-C., Fang, H.-Y., Wang, B., Huang, T.-H., & Shie, M.-Y. (2017). The effects of Biodentine/polycaprolactone three-dimensional-scaffold with odontogenesis properties on human dental pulp cells. International Endodontic Journal, 51, e291-e300. doi:10.1111/iej.12800

:

|